Tips for Designing a Perfectly Embroidered Logo on your Cap

By: Melody D Posted on: Nov 3, 2021You have a great design, but it doesn’t look exactly the same on the cap. Has this ever happened to you?

If yes, read on as this blog aims to give you effective tips on creating logos that look great in design and in embroidery. You will also learn more about embroidery, the digitizing process, and how to design for popular cap styles. Let's get started.

What is Embroidery?

Embroidery is a decoration technique in which the design is sewn directly onto the fabric. The classy appeal and long life of embroidery decorations make them a popular option for creating promotional products and customized blank apparel like t-shirts, polos, bags, caps, and more.

Consider your customer preference and choose a style that will appeal to them—whether that's a flat-bill snapback or a traditional baseball cap.

Embroidery can be done in different methods such a flat, 3D, applique, sequin, chenille, and more. This article will focus on flat and 3D embroidery for caps.

In flat embroidery, the decorative stitch is applied directly to the fabric to create the design.

In 3D embroidery (aka puff or foam embroidery) a foam is placed on the fabric. When the stitches are made over the puffs, the design will protrude from the surface creating a three-dimensional effect.

Below is a comparison of the same design in flat and 3D embroidery.

As you see, cap embroidery can create stunning results. However, some aspects of embroidery need extra attention because the curve of the hat can present some unique challenges. Let’s see what they are.

Design Tips

Embroidering complex designs is extremely difficult, and sometimes even impossible. So it is best to leave out any intricate patterns, small texts, and minute details from your design. Besides, a simple design creates the best visual impact with its elegant appeal and tight stitches.

Here is how our designers got a complex design ready for embroidery.

This also applies to 3D embroidery. Due to the foam being applied underneath the stitching, 3D embroidery works best for simple designs, like initials or monograms as shown in the image below.

Calligraphy fonts are not recommended for 3D embroidery as the thin lines between the letters could cause issues. Instead, choose solid block letters fonts.

Apart from complexity, there are a few other factors that you should be mindful of when creating an embroidery design. They are

-

Design Size

Height

We recommend a maximum height of 2.25 inches for cap embroidery designs as this is a trusted estimate that works smoothly for most cap styles and machines.

Apart from complexity, there are a few other factors that you should be mindful of when creating an embroidery design. They are

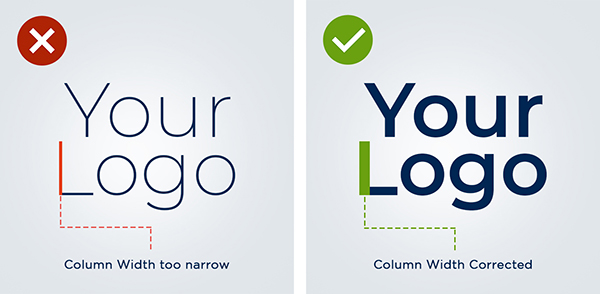

Width

The width of the design is also critical to the quality of the embroidery. Wide designs on smaller caps will not look great and could cause sewing issues. While It is possible to use designs with a 5.25” width for larger caps, 4.5” is a reliable choice for most cap styles and machines.

CapBargain ProTip:

Our experts recommend scaling your designs to a maximum of 4.5” to 2.25” for optimal results.

-

Size of design elements

For Flat Embroidery

The size of individual elements in the design is as important as the dimension of the design as a whole. A minimum height of 0.2 inches is recommended for text with uppercase letters. If you are using a mix of upper and lowercase characters, keep the height of uppercase letters to a minimum of 0.25 inches so the smaller letters are not too small and illegible for embroidery.

For 3D Embroidery

For 3D embroidery, our in-house experts recommend keeping a minimum thickness of 3mm for all text in the design.

Here is how it will look in a sample logo.

-

Colors and Gradient

Our minimalistic approach to design extends to the choices of colors as well. Sticking to a few colors will give you the best visual impact. A detailed image with lots of colors and gradients will have to be simplified for embroidery.

Digitizing Tips

Now that we have an embroidable design at hand, it is time to digitize it.

Digitizing is the process of converting a design into a digital stitch file. The digitized file tells the machine how to move the needle and where to place the stitches to recreate the design in embroidery.

When to Re-digitize

A digitized file is not one-size-fits-all. Sometimes you will have to redo the digitizing process. It is better to re-digitize the design if you are-

-

Changing the design size

One of the most common cases where you need to re-digitize is when you are changing the size of the logo. This is necessary to ensure that the stitchings are properly placed by the machine.

-

Changing the apparel

If you are embroidering on caps, using a file designed for flat apparel like a blank wholesale T-shirt will not produce a high-quality design. And a design digitized for a structured cap like 32-467 may not work well on an unstructured cap like 18-772.

-

Changing the embroidery type

Each style of embroidery requires a separate digitized file. This means that your successful design for flat embroidery could fail if you use it for 3d without re-digitizing.

-

Changing the machine

A logo digitized for one machine might not give the best results with another one. If you digitize the design by yourself but rely on a 3rd party embroidering service, make sure to check the compatibility of the file with their machine.

Cap Style Tips

Depending on which cap you choose, there are some minor adjustments to be made.

Beanies

Creating embroidery on blank beanies is a tad tricky due to their flimsiness. Our experts recommend stitching a fill fabric of the same color on the design area to make your embroidery perfect.

Foam-front caps

In foam caps, stitches often get sunk into the surface and will not give the result you expect from embroidery. If this is not your preferred look, heat transfer decoration is recommended.

Structured and unstructured caps

Unstructured caps require backing (stabilizers) to hold them in place. Structured caps, on the other hand, don't need backing as the thick fabric will provide the required stability. However, we recommend using a tearaway cap backing regardless of the cap structure for the best results.

6-panel Caps

Embroidering on blank 6-panel caps can be tricky due to their center seam. If you have a thin vertical line in the design (or letters like “l” or “i”), it will fall at the gap of the seam and would not look great. Other elements of the design could also get distorted if they pass through the seam. You can solve this by shifting the design sidewise to avoid hitting the center seam.

The final stitch

Hopefully, you now know how to design the perfect logo for your cap embroidery.

However, if you want to create awesome-looking cap logos without getting boggled by the intrinsic details, head to https://capbargain.com/create-your-own where you can do just the same with a few clicks.

Select high-quality clipart from our library or upload your own design, and you will get the perfectly embroidered caps delivered to your doorsteps. And don’t forget to get in touch with our Customer Support Team at https://capbargain.com/contact if you need any assistance at all.